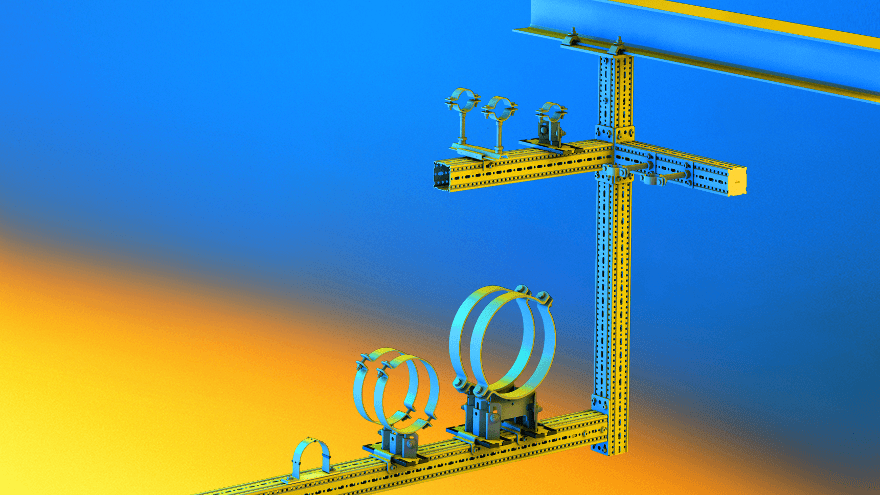

Simotec – Off-the-shelf, adjustable height modular pipe shoes

-

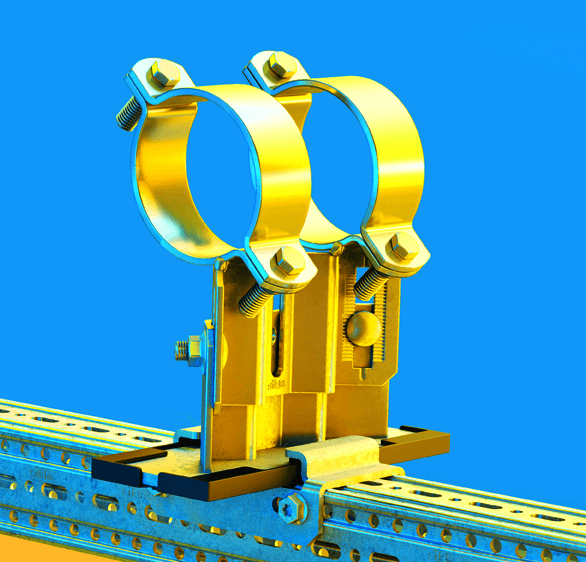

As for the modular steelwork support systems, our adjustable height pipe shoes under the brand name “Simotec”, follow the same principles of modular product design. With a standard pipe range up to 600NB (24”), the common modular components of each shoe base plate allow for an ‘upgrade’ to become a guide or fixed point by simply attaching the relevant bracket piece to the attaching Ibeam or siFramo steelwork.

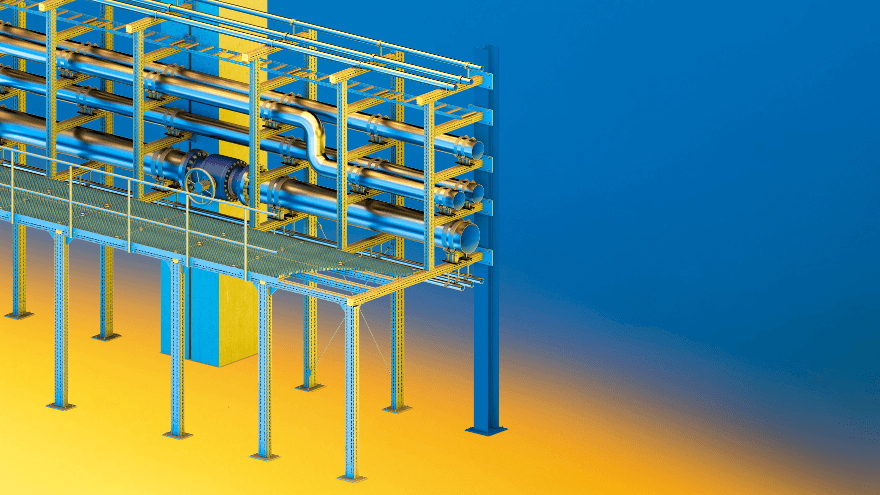

Detailed Engineering / Piping Design Integration

All modular steelwork support systems and pipe shoes can be fully implemented into the detailed engineering phase, allowing for accurate modelling / clash-check control and generation of BOM breakdowns. Plant design and modelling software plug-in tools are available for these complete ranges.

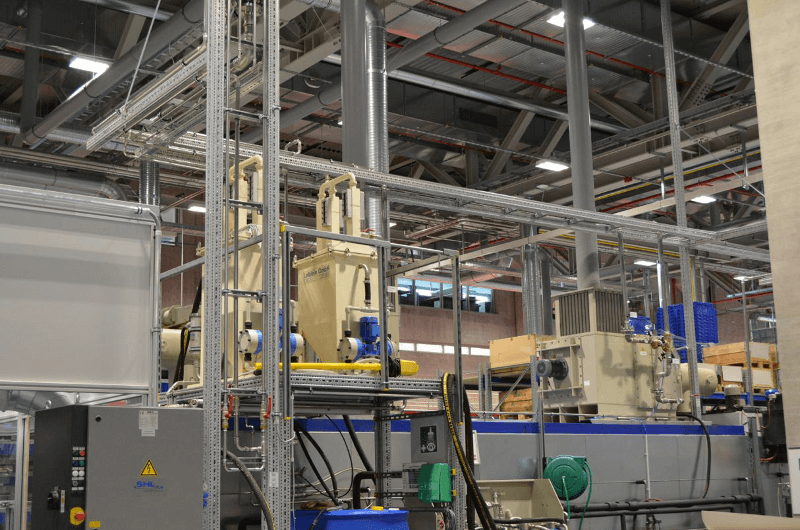

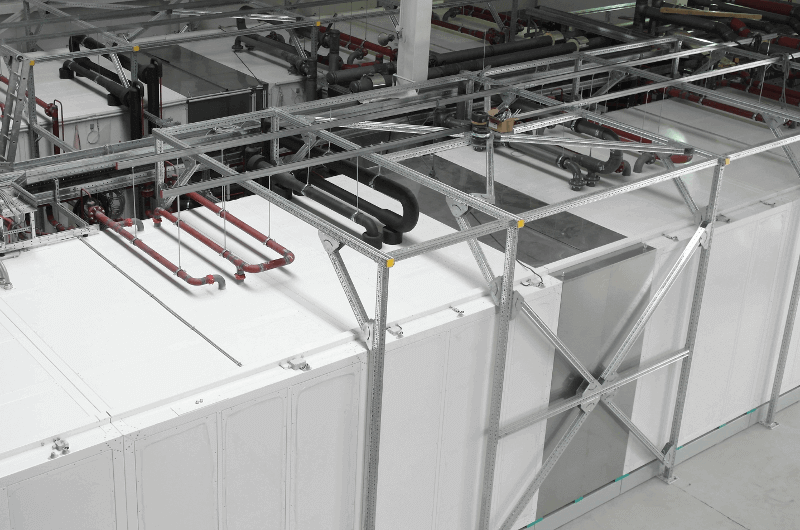

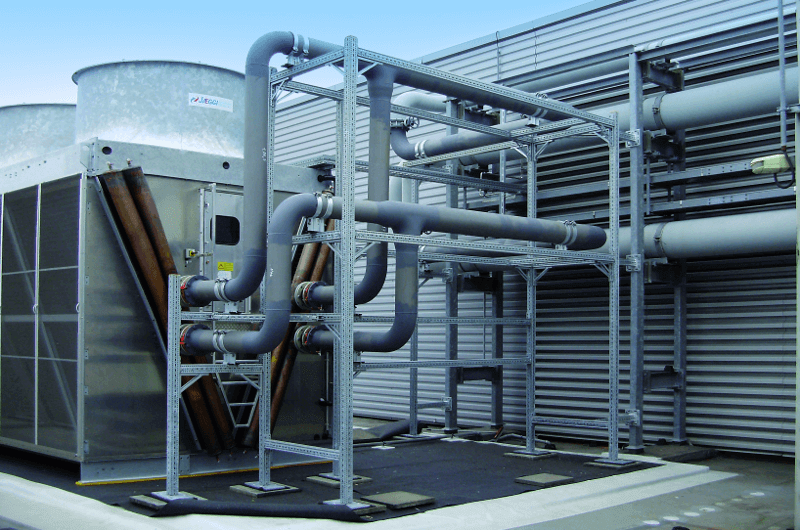

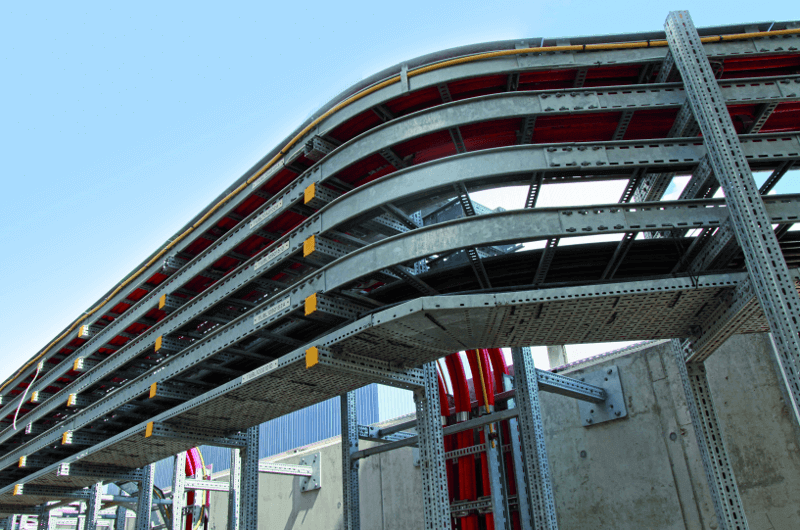

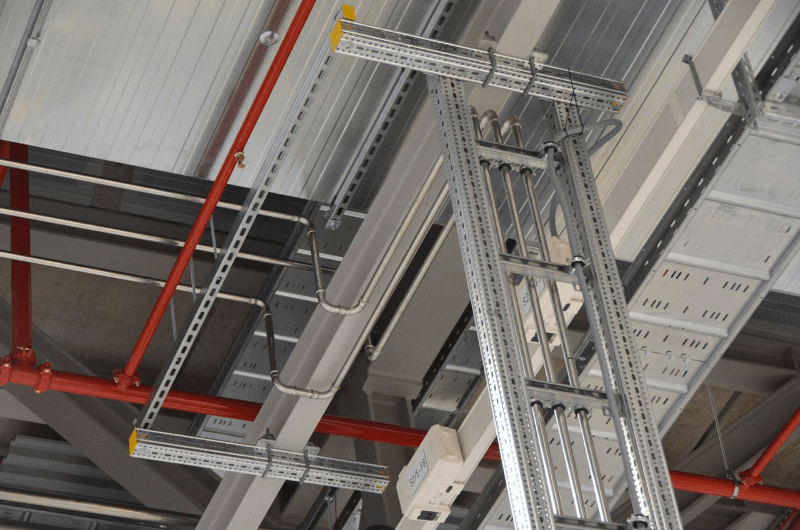

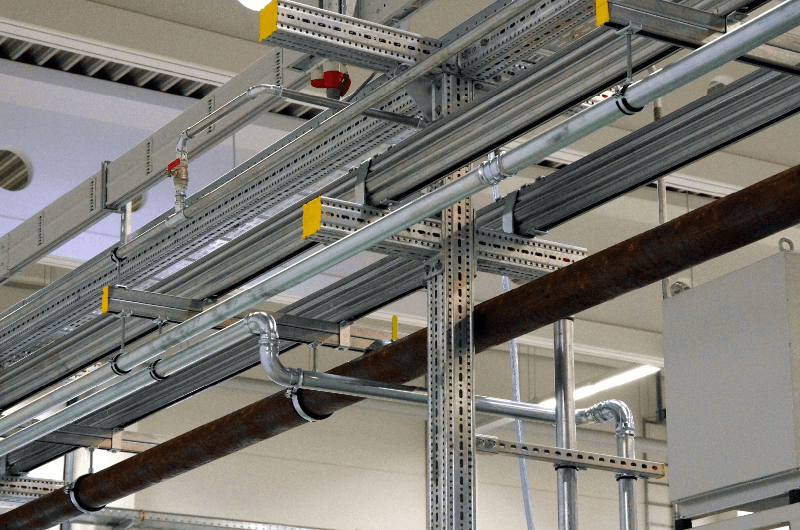

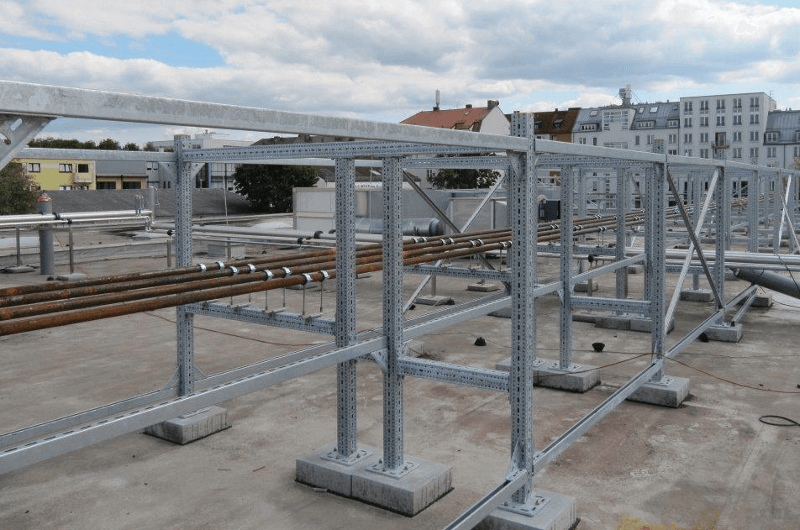

Modular Steelwork Support System

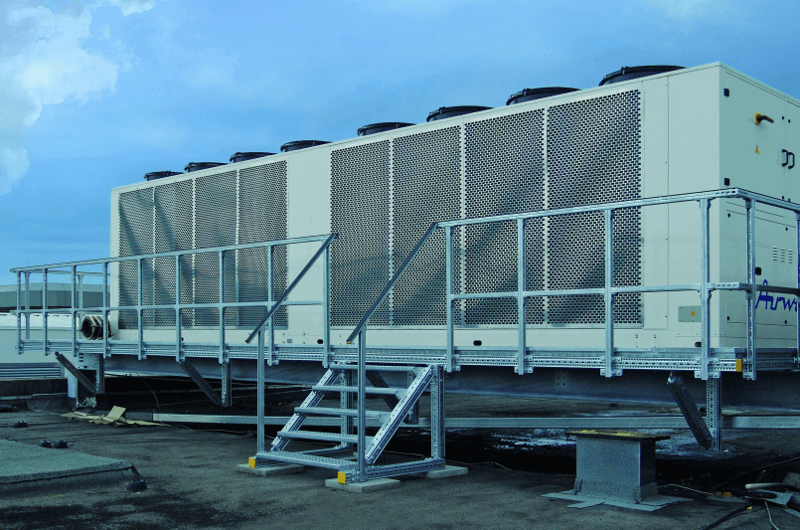

siFramo is a versatile modular steelwork support system for the construction of frames and supporting structures without the need for welded connections in either field-fit or fab-shop installations of the system. siFramo allows multidirectional connection possibilities without the need for through-bolts and back-plates. The box sections have a higher torsional resistance than conventional beam profiles but a significantly lower equivalent weight (lbs/foot).

siFramo sections are available in metric sizes:

- 3 mm (11 gauge) - 80/30 and 80/80

- 4 mm (8 gauge) - 100/100 and 100/160

siFramo connectors are assembled to the sections using thread forming screws, thereby offering a superior process-reliable vibration-proof fastening.

One system - many advantages:

- No welding to connect the system together. No hot works permits required.

- Higher performances achievable relative to lower overall weight of steel

- Maximum flexibility, minimum installation time

- Modifications to the installation can be made quickly, with no need to fully disassemble the connecting component

- Parts reusable. Minimal to zero waste

- Compatible with primary steel structure or when fastening support to concrete

- One thread-forming screw for all system component connections

- System compliance with the quality requirements of ISO3834 / IIW

- Plant design and modelling software plug-in tools available

- Special coatings available for highest corrosion resistance requirements

Downloads

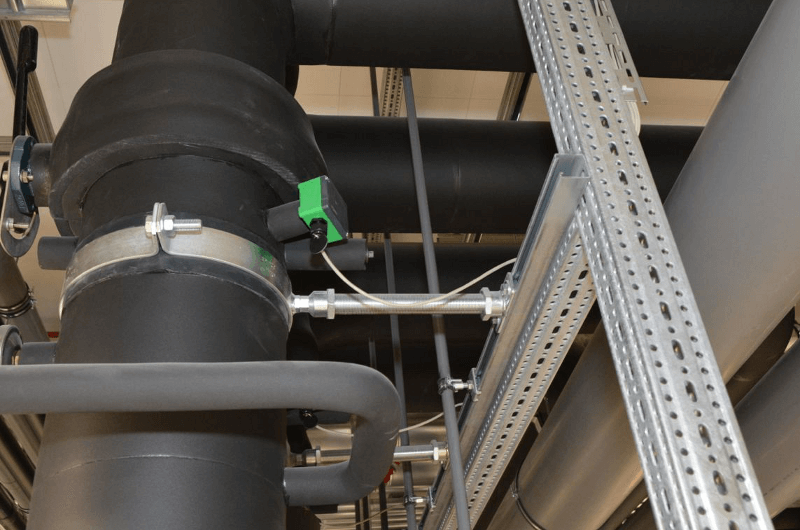

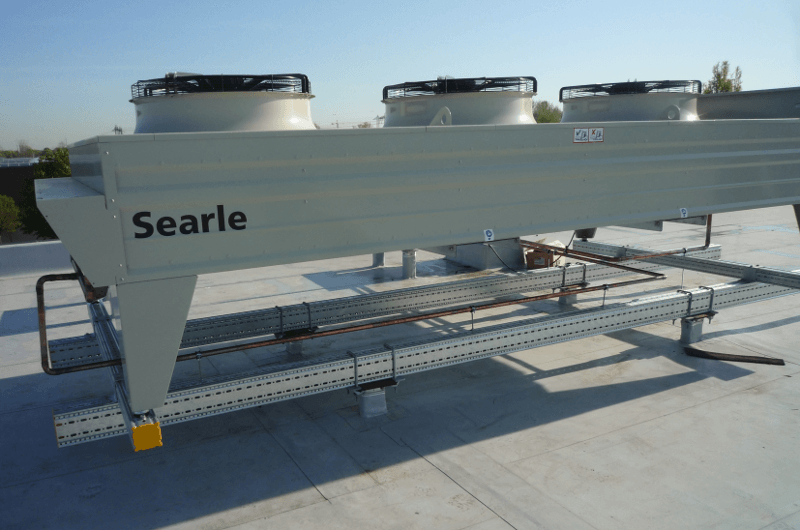

Adjustable Pipe Shoes

Like our steel-framing-systems, our adjustable pipe shoes under the brand name “Simotec”, follow the principles of modular product design. The combination of base plate, adjustable web and pipe clamps forms a range of pipe shoes for up to 600NB diameter. Modular components allow for an “upgrade” of any individual pipe shoe to become a “guide” or a “fixed point” both, by attaching to existing traditional steel or by adapting to our Sikla-specific steel sections.

Benefit from the advantages!

- Benefit from simplified stock logistics.The combination Slide Support + Set allows to build either a Guided Support or a Fixed Point, according to the requirements.

- Guided and fixed point sets are available for all common beam sizes e.g. siFramo, STF 120, as well as for normed profiles.

- Higher loads and simple height adjustment by means of the innovative design.

- The complete modular system is integrated as a sub-library into all current software-planning aides